![]()

![]()

Reordering Automation allows for the automated replenishment of non-grid SKUs from a designated Distribution Center or the replenishment SKU Vendor.

Note: Grid products use the Model Stock/Replenishment functionality for reordering. The system displays a message if you are using a SKU that is assigned to a grid product.

Location Automation is enabled by SKU and location (Location Hierarchy) by creating a Reorder Record and checking the Auto Reorder box on the Reordering Record. Reordering Automation requires that a default shipping method be set for the SKU.

A process runs once nightly evaluating all Reorder records to see if the Min. Level is reached. if it is, then the sku and reorder qty is determined using the Reorder Method and Qty for that Reorder record. The SKU and reorder qty is then added to the purchase order or transfer queue. If the sku and location already exist in the purchase order or transfer queue then the reorder quantity would be recalculated and updated accordingly.

Purchase orders can then be reviewed, updated and committed as needed by the retailer See Purchase Order Queue for more information.

Transfers can then be reviewed, updated and committed as needed by the retailer See Transfer Queue for more information.

|

Step |

Action |

|

1 |

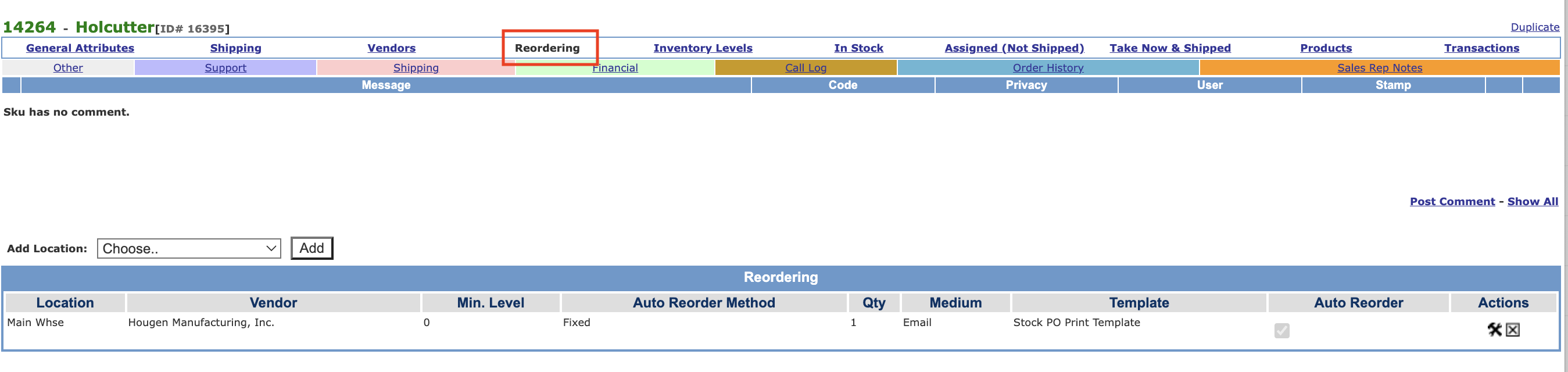

Click on the Reordering link as shown above. |

|

2 |

Select the Location (Location Hierarchy) from the drop-down list and click Add. The Edit Reorder popup window will appear populated with the Location, Default Fulfillment Vendor and Default Fulfilment vendor Unit Cost.

|

|

3 |

Enter the reorder recorder infromation.

Min Level - This is the threshold for initiating reordering automation. If sum of Stock + In PO + In Transfer To + In Purchsae Order Queue - Backordered total is less than the Min Level then reordering automation kicks in. Reorder Method - This defines how the reorder quantity is calculated.

Example SKU 825ra-baseball has an In Stock+ In Stock PO, + In PO Builder + Reserved = 14. Since this total is less than the Minimum Level of 16, the Auto Reorder Quantity of 10 is added to the PO Queue.

Example SKU 825ra-baseball has an In Stock+ In Stock PO, + In PO Builder + Reserved = 14. Since this total is less than the Minimum Level of 16, the Auto Reorder Quantity of 2 is added to the PO Queue.

Replenishment Vendor - Vendor to use for Reordering automation. Autoreorder Delivery Method - Email, Print, EDI or eFax. Autoreorder Template - Email or Document Template to use for purchase order or transfer created during reorder automation. Use Distribution Center - Indicate whether to reorder from a Distribution Center, if one exists. Auto Reorder - Enabled by default. To pause Reordering Automation uncheck the box. |

Important: The quantity calculated for each stock purchase order is the original ordered amount and does not take into account the quantity of inventory on the purchase order either received or voided to date.

Update

Click Update to apply entries or changes. Click Close to close the popup window.

Click the ![]() to edit a record. The Edit Reorder popup window will appear, make your changes and click Update to apply. Click Close to close the popup window.

to edit a record. The Edit Reorder popup window will appear, make your changes and click Update to apply. Click Close to close the popup window.

Click ![]() to delete a record. This is the only way to remoeve a reorder record.

to delete a record. This is the only way to remoeve a reorder record.

Reordering records can be imported using the Data Import. Data mapping will be requried so contact CORESense Customer Support for assistance in setting up the Product and SKU and/or the SKU Only import for reordering im[ort.

© 2023 CORESense · info@coresense.com · 125 High Rock Avenue, Saratoga Springs, NY 12866